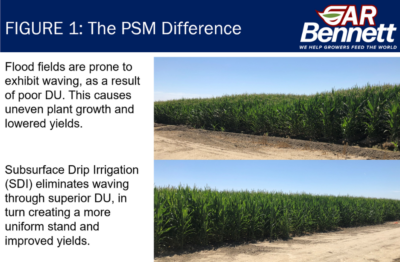

SDI is known to produce a superior distribution uniformity (DU), removing water from the weed seedbank and delivering it right to the crop root zone. By spoon feeding water directly to the source, the roots of the triticale receive enough nutrients to maintain good health and support the seed head, eliminating the chances of lodging. The same can be said for silage: superior DU eliminates “waving”, in turn creating a more uniform stand and improved yields (Figure 1). Superior DU also minimizes weed pressure both in-field and on the borders, meaning there is less competition for nutrients and water. Tractor passes through the field are limited as the need for spraying/mechanical weed management is reduced or even eliminated.

SDI is known to produce a superior distribution uniformity (DU), removing water from the weed seedbank and delivering it right to the crop root zone. By spoon feeding water directly to the source, the roots of the triticale receive enough nutrients to maintain good health and support the seed head, eliminating the chances of lodging. The same can be said for silage: superior DU eliminates “waving”, in turn creating a more uniform stand and improved yields (Figure 1). Superior DU also minimizes weed pressure both in-field and on the borders, meaning there is less competition for nutrients and water. Tractor passes through the field are limited as the need for spraying/mechanical weed management is reduced or even eliminated.

Since 2019, the 38.1-acre field has produced a triticale crop and silage crop on SDI (second triticale crop was recently harvested). The field was strip-tilled between triticale harvest and silage corn planting to further increase conservation efforts. Our PSM team tracked the tonnage data and crop quality from these harvests to ensure the SDI was working efficiently. Overall, the farmer saw an 18.6% increase in harvestable yield from both crops on a fraction of the typical flood irrigation method. DU also increased to 93%.

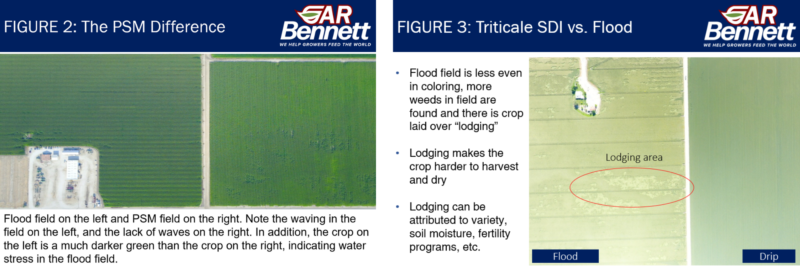

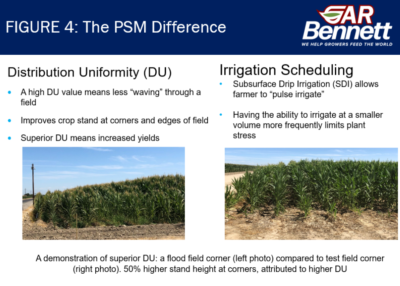

By installing SDI, the farmer was able to judiciously apply water by irrigating right to ET. Aerial images were taken to compare the SDI field to surrounding flood fields. As you can see, the flood fields have less even coloring and severe “waving” (Figure 2). Not only does this make the crop more difficult to harvest, but it also slows down the harvest process and creates a major loss in crop value. The SDI field on the other hand has no lodging or waving which will make for a faster, more efficient harvest (Figure 3).

By installing SDI, the farmer was able to judiciously apply water by irrigating right to ET. Aerial images were taken to compare the SDI field to surrounding flood fields. As you can see, the flood fields have less even coloring and severe “waving” (Figure 2). Not only does this make the crop more difficult to harvest, but it also slows down the harvest process and creates a major loss in crop value. The SDI field on the other hand has no lodging or waving which will make for a faster, more efficient harvest (Figure 3).

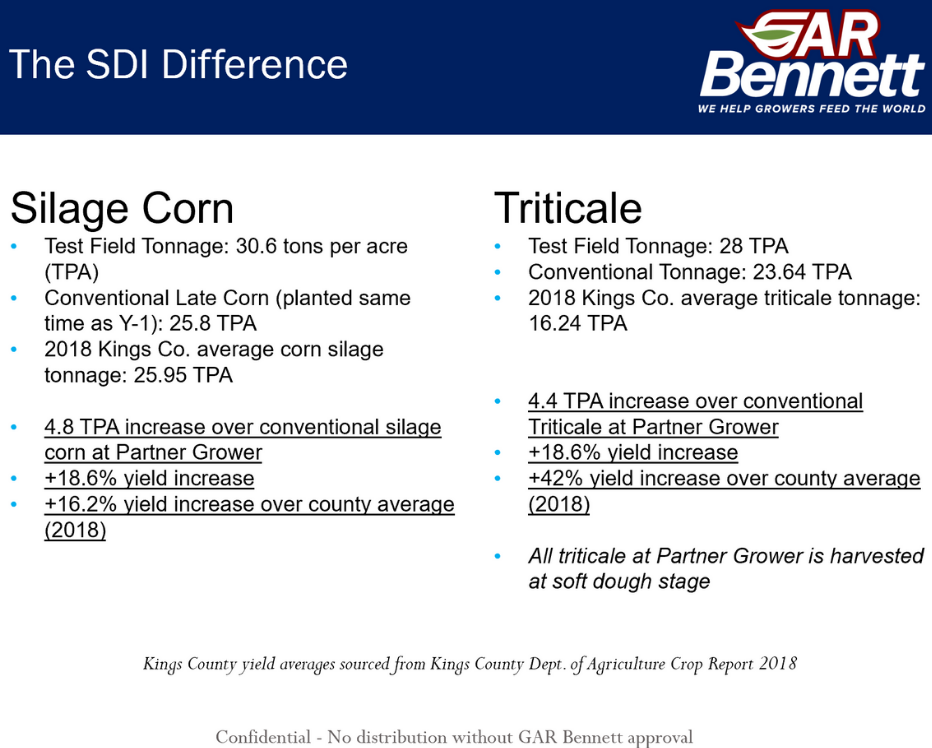

Our automation team also took part in this project, installing back flush control valves on the tanks. These valves will assist the farmer in their preventive irrigation maintenance program, ensuring the tanks and SDI stay clean while pressure and flow remain constant. The irrigation scheduling was automated to “pulse irrigate.” This is an additional technique incorporated into SDI that allows the farmer to irrigate at a smaller volume more frequently to limit plant stress (Figure 4). The team set up the irrigation system with the capability of running and/or blending effluent water with fresh water if the farmer chooses to do so.

So, what is the difference with SDI? Our PSM team gathered data from both harvests, compared it to the Kings County Department of Agriculture 2018 Crop Report and found the following:

Overall, this farmer saw a total benefit per acre of $407.48 on yield alone.

Triticale:

- 4 TPA increase X $38.50/ton* = +$169.40/acre

Silage Corn:

- 8 TPA increase X $49.60/ton* = +$238.08/acre

* Crop values sourced from 2018 Kings County Department of Agriculture Report.

SDI is not only an added value product for silage crops, but forage crops as well. Our team of PSM experts were able to assist this farmer in achieving more yield on less water and provided proven results. If your silage management program is lacking, don’t hesitate—call our team today to help you save and keep your operation moving.